Product Description:

The Mullite ceramic product is an advanced mullite ceramic material renowned for its exceptional thermal and mechanical properties. Composed primarily of 3Al2O3·2SiO2, this unique chemical composition endows the material with outstanding stability and performance in demanding environments. As a high temperature mullite ceramic, it is specifically engineered to provide superior resistance to thermal stress, making it an ideal choice for applications requiring durability and reliability under extreme conditions.

One of the key attributes of this mullite ceramic product is its low thermal expansion coefficient, ranging from 4.5 to 5.5 × 10⁻⁶ /K. This characteristic ensures minimal dimensional changes when exposed to temperature fluctuations, significantly reducing the risk of cracking or deformation during rapid heating or cooling cycles. This property is critical for components used in high temperature environments, where thermal expansion mismatch can lead to premature failure. Accordingly, the mullite ceramic thermal insulator serves as an excellent material for protecting sensitive equipment and maintaining structural integrity.

In addition to its thermal stability, this mullite ceramic exhibits impressive mechanical strength, with values ranging between 200 and 300 MPa. Such robust mechanical performance allows it to withstand substantial mechanical stresses and pressures without compromising its structure. This strength, coupled with its relatively low density of 3.1 to 3.2 g/cm³, provides an optimal balance between durability and weight, making it suitable for applications where both strength and lightweight characteristics are essential.

Another notable feature of the advanced mullite ceramic material is its exceptional thermal shock resistance, rated at 250. This high level of resistance enables the ceramic to endure sudden and extreme temperature changes without cracking or losing its mechanical integrity. Thermal shock resistance is a critical parameter for materials used in furnaces, kilns, and other high temperature processes where rapid temperature variations are common. The mullite ceramic thermal insulator’s ability to maintain performance under such conditions extends the lifespan of components and reduces maintenance costs.

The combination of these properties makes this mullite ceramic product an ideal solution for a wide range of industrial applications. It is widely used in the manufacturing of refractory components, kiln furniture, heating elements, and thermal barrier coatings. Its chemical stability and resistance to corrosion further enhance its suitability for harsh chemical environments and high temperature processes. As a high temperature mullite ceramic, it performs reliably in environments where other materials might degrade or fail.

In summary, this mullite ceramic product stands out as a high-quality, advanced mullite ceramic material offering excellent thermal insulation, mechanical strength, and durability. Its low thermal expansion coefficient and high thermal shock resistance make it especially valuable for applications involving extreme temperature variations. With a balanced density and robust mechanical properties, it provides a versatile and dependable solution for industries requiring high performance ceramics. Whether as a mullite ceramic thermal insulator or a structural component in high temperature systems, this product delivers consistent and reliable performance, meeting the rigorous demands of modern industrial applications.

Features:

- Product Name: Mullite Ceramic Thermal Insulator

- Hardness: 7 - 8 Mohs

- Melting Point: 1840 - 1850 °C

- Porosity: Typically <15%

- Working Temperature: 1400℃

- Thermal Expansion Coefficient: 4.5 - 5.5 × 10⁻⁶ /K

- Excellent performance as a High Temperature Mullite Ceramic

- Reliable Mullite Ceramic Thermal Insulator for demanding thermal applications

Technical Parameters:

| Thermal Conductivity |

3.5 - 4.5 W/m·K |

| Chemical Composition |

3Al2O3·2SiO2 |

| Origin |

China |

| Thermal Shock Resistance |

250 |

| Mechanical Strength |

200 - 300 MPa |

| Working Temperature |

1400℃ |

| Color |

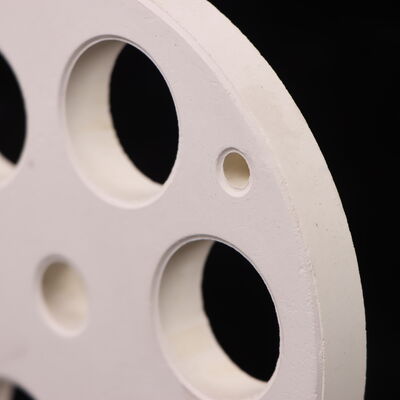

White To Light Brown |

| Hardness |

7 - 8 Mohs |

| Porosity |

Typically <15% |

| Dielectric Constant |

6 - 7 |

Applications:

The KAMTAI Mullite Ceramic product, model number MOLAISHITAOCI, is an advanced mullite ceramic material specifically engineered to meet a wide range of industrial and commercial application occasions and scenarios. Originating from China and certified under ISO 9001, this product is recognized for its superior quality and consistent performance. Its thermal conductivity ranges between 3.5 to 4.5 W/m·K, making it an excellent choice for applications requiring efficient thermal insulation.

One of the primary application occasions for this engineered mullite ceramic material is in high-temperature environments where thermal shock resistance is crucial. With a thermal shock resistance rating of 250, the Mullite Ceramic Thermal Insulator is ideal for use in furnaces, kilns, and other heat treatment equipment. It effectively protects sensitive components from rapid temperature changes, thereby enhancing durability and operational reliability.

The mechanical strength of the KAMTAI Mullite Ceramic product, rated between 200 to 300 MPa, ensures that it can withstand significant mechanical stress. This makes it suitable for use in structural components within the electronics, automotive, and aerospace industries, where both mechanical robustness and thermal insulation are required. Its dielectric constant of 6 to 7 also makes it an excellent insulating material in electrical and electronic applications, where maintaining electrical isolation under high temperatures is essential.

The product's color ranges from white to light brown, adding to its aesthetic versatility for use in visible components or decorative industrial parts. KAMTAI packages this advanced mullite ceramic material in sturdy wooden boxes to ensure safe and secure delivery. With a supply ability of 500,000 pieces per month and a minimum order quantity of 1000 pieces, it is well-suited for large-scale industrial procurement. Delivery is prompt, typically within 30 days after payment, and payment terms are convenient with TT options available. Pricing is negotiable to accommodate different customer needs and project scales.

In summary, the KAMTAI MOLAISHITAOCI Mullite Ceramic Thermal Insulator represents an ideal solution for industries requiring an advanced, reliable, and high-performance mullite ceramic material. Whether it is for thermal insulation, mechanical protection, or electrical insulation, this engineered mullite ceramic material excels in diverse application scenarios, providing long-lasting performance and exceptional value.

Customization:

KAMTAI offers customized Engineered Mullite Ceramic Material products under the model number MOLAISHITAOCI, proudly made in CHINA. Our Mullite Ceramic Thermal Insulator solutions are certified with ISO 9001, ensuring top quality and reliability for your applications.

We specialize in providing Engineered Mullite Ceramic Material with superior properties including a porosity typically less than 15%, a high working temperature of 1400℃, thermal conductivity ranging from 3.5 to 4.5 W/m·K, hardness between 7 to 8 Mohs, and an impressive melting point of 1840 - 1850 °C.

Our supply ability is 500,000 PCS per month, with a minimum order quantity of 1000 PCS. We package all products securely in wooden boxes to ensure safe delivery. Delivery time is 30 days after payment, with payment terms via TT. Pricing is negotiable to best meet your business needs.

Choose KAMTAI for your customized Engineered Mullite Ceramic Material and Mullite Ceramic Thermal Insulator needs, and benefit from high-performance ceramics designed specifically for your requirements.